Nonflammable wood is a wood that does not burn easily. In order to produce non-flammable wood, it is artificially injected with a chemical known as a flame retardant. This may sound a bit negative, but I would like to give you an accurate picture of the current situation.

Boric acid, phosphoric acid and their compounds are the most common flame retardants used in wood. Since it is a high performance wood, it is thought to have applications in various places, but in reality, it is not very popular or widespread, to tell the truth. But to be honest, it is not so popular or spreading, because it has a definite disadvantage to use, and its storey is quite difficult to use.

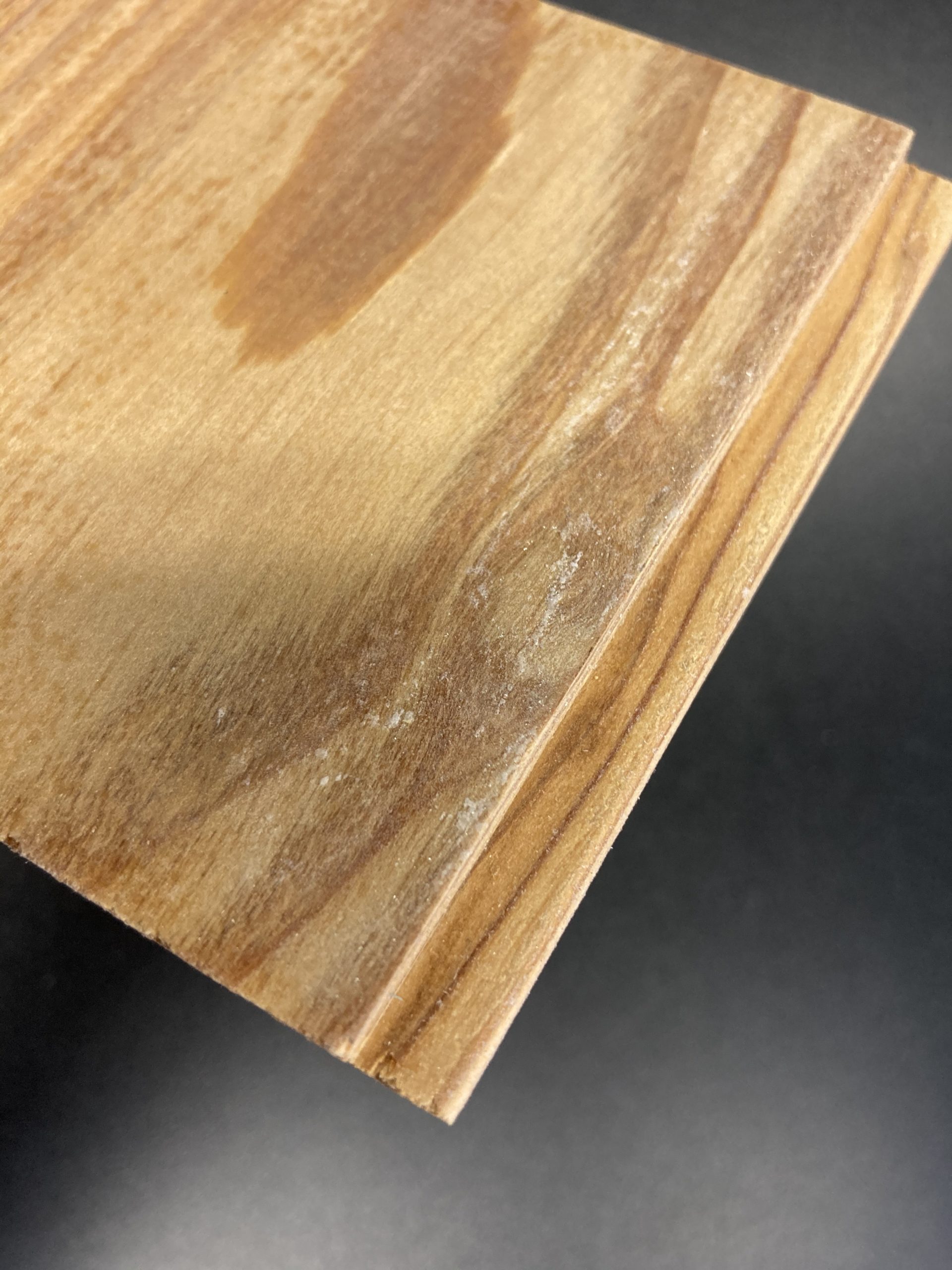

There are two main drawbacks. These are sores and white flowers. Let’s start with the sags.

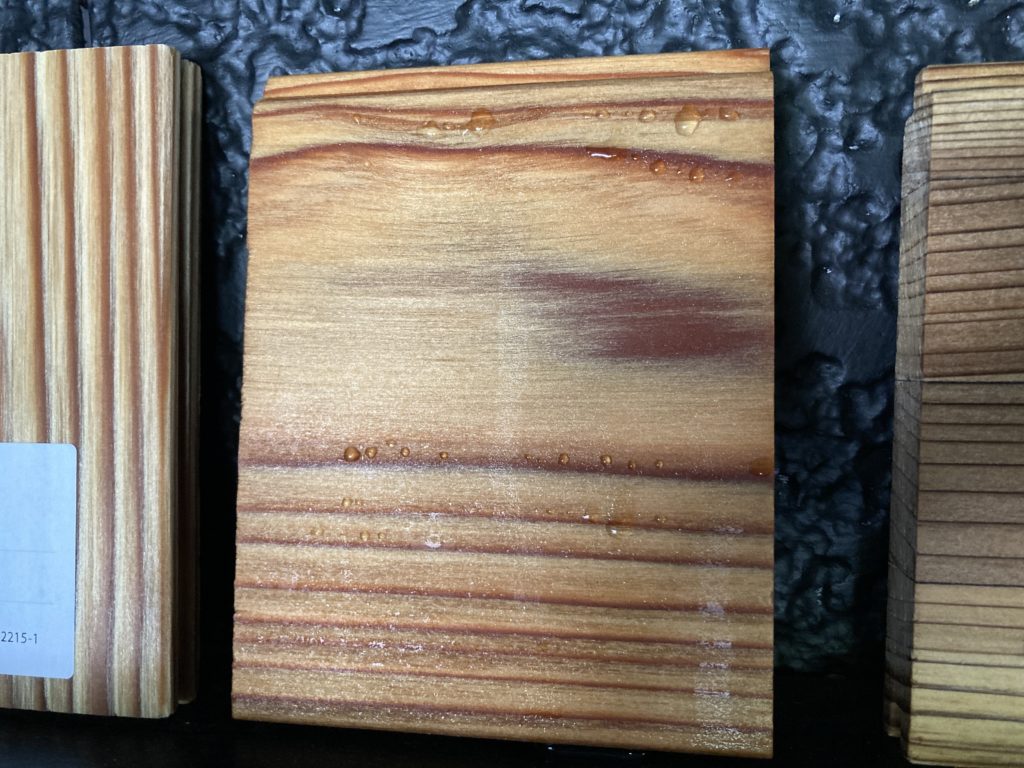

Look at this picture. There are water droplets on the surface, as if you were sweating.

.

.

This is a sample of noncombustible wood impregnated with a phosphoric acid fire retardant, which was observed in a semi-outdoor location not exposed to rain and not badly ventilated during the rainy season in July. This is a product that is currently being sold by a certain manufacturer. The water droplets on the surface are thought to be the dissolution and removal of the agent. The phosphoric acid reacts with moisture in the air and causes a dripping phenomenon. It is difficult to use this product as a design agent in this state.

.

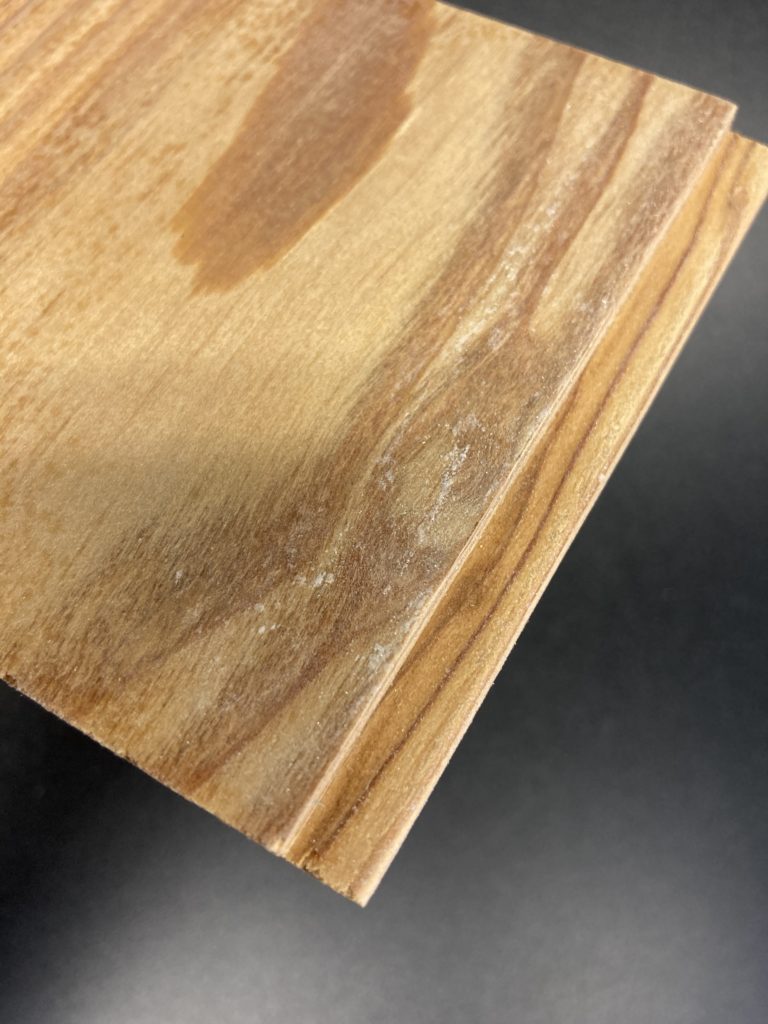

Incidentally, the non-combustible wood shown below appears to be painted. This is due to the fact that it absorbs moisture. It is not wet.

These are not wet.

.

.

.

It’s hard to see from the photo, but the flame retardant that has dried will harden on the surface, leaving a rough residue or sticking to the surface. This occurs in about 7 days from the new condition, making it a difficult material to handle.

.

We followed up from here for another month (August). Summer has come and the humidity has dropped and the wood has dried out. However, the small mouth is still wet. The dissolved and dripped phosphoric acid medicine hardened on the surface and became coarse and white. It is difficult to use it on the design surface because of the rough surface when you touch it.

.

As a countermeasure, you can coat or paint the surface, but be careful because the coating agent is flammable and cannot be recognized as a non-combustible material. Also, if you are within your reach, wiping with water when a drip occurs can reduce the adherence of the surface. However, strictly speaking, the flame retardant will be reduced because the chemical will be removed from the surface of the wood. Wood flame retardants are essentially water-based. Therefore, they can be dissolved in water or hot water.

However, if the surface has hardened as shown above, it is difficult to wipe it off by wiping with water or hot water. If you don’t scrape the surface again, a clean surface will not come out.

.

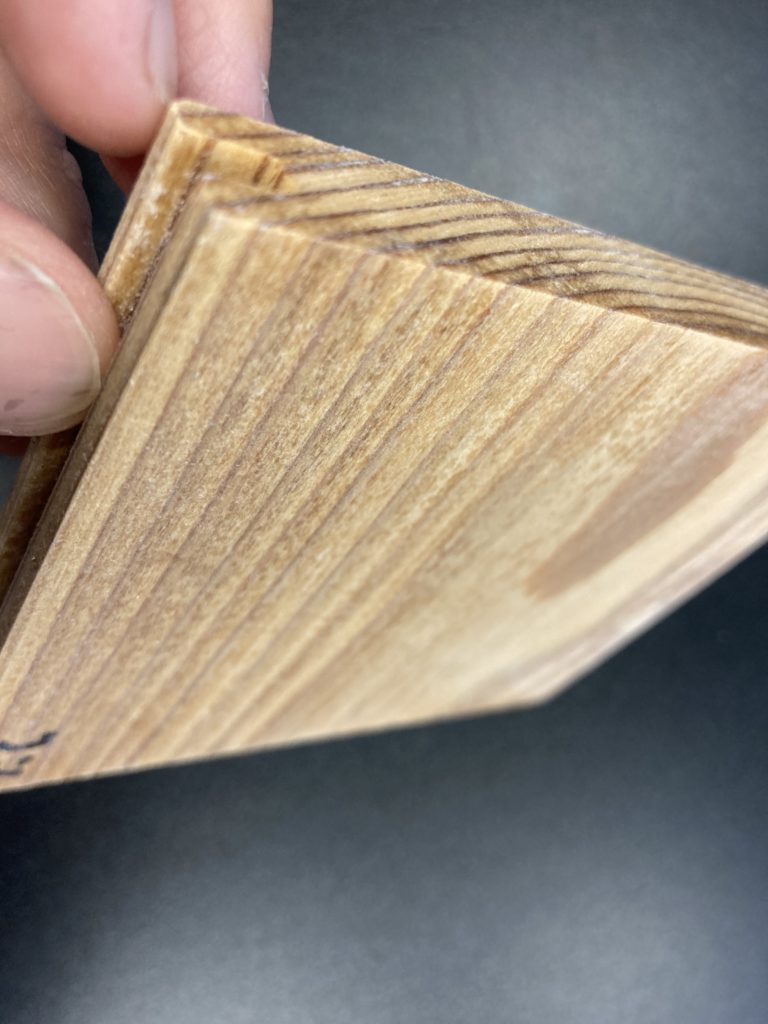

This noncombustible wood is also made by another manufacturer and is impregnated with a phosphate fire retardant. It is said to be a noncombustible wood that has been treated against liquid dripping and smearing, but the surface along the grain of the wood is white and smearing is occurring. It does not cause any sagging, but it absorbs moisture, and it is hard to call it a dry wood. It is much easier to handle than the above-mentioned manufacturer’s product, but it also became moist in 7 days, and its overall color has changed and it has stained. It is difficult to apply it to places where it will be used for several years.

.

This noncombustible wood is also made by another manufacturer and is impregnated with a phosphate fire retardant. It is said to be a noncombustible wood that has been treated against liquid dripping and smearing, but the surface along the grain of the wood is white and smearing is occurring. It does not cause any sagging, but it absorbs moisture, and it is hard to call it a dry wood. It is much easier to handle than the above-mentioned manufacturer’s product, but it also became moist in 7 days, and its overall color has changed and it has stained. It is difficult to apply it to places where it will be used for several years.

.

.

.

We have been following it for another month or so (August) in the same place from here. It looks like the sycamore has progressed. Even though sycamore prevention measures are taken, it is difficult to use this wood for design purposes because it shows a certain amount of sycamore in this period of time. After all, it is difficult to prevent nonflammable wood from staining.

.

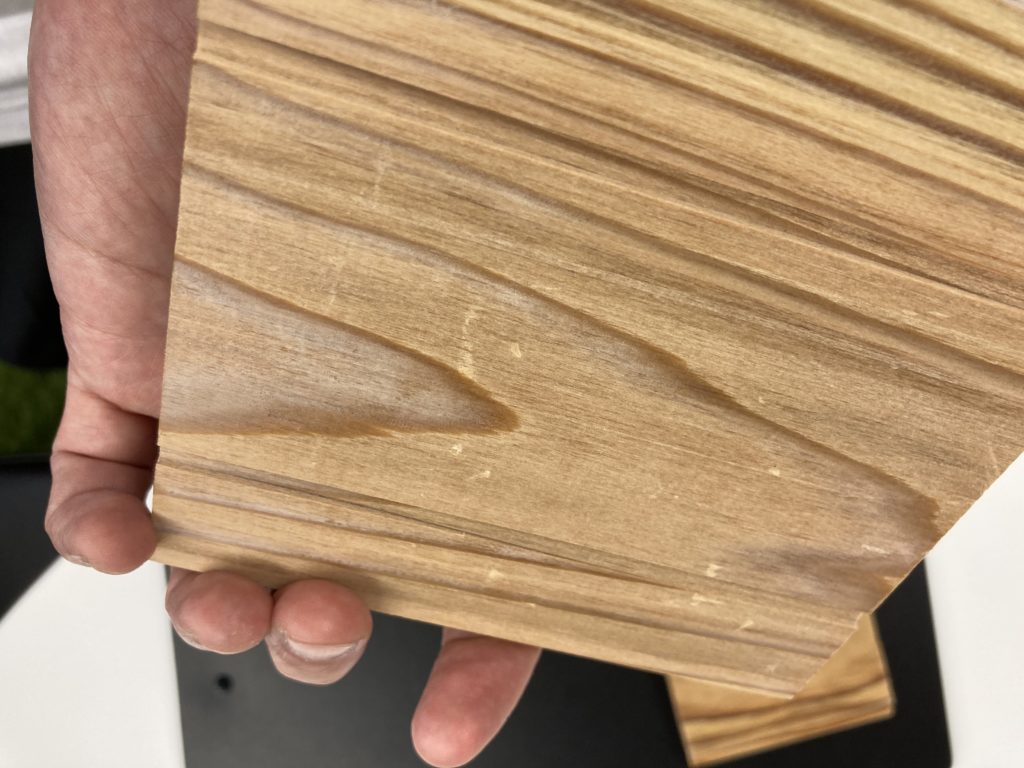

Here’s the initial situation. It is not white. If you put it in a plastic bag to protect it from moisture, it will not change significantly over time.

.

.

Here’s a sample of SOUFA impregnation. So far, no white-flowering has been done.

.

.

We have been researching non-combustible wood since our founding, but we have yet to solve the problems of dripping and white bloom. Wood is a material that symbolizes Japanese style architecture, so wooden buildings are attracting attention in time for the Olympics. Also, it is actually being used in large buildings. However, these buildings will also have to deal with the phenomena of dripping and white bloom in the future.

.

Our company originally originated as a non-profit organization with the goal of disaster recovery. Within that organization, we have researched, and are still researching, non-combustible wood. However, even from such an industry insider’s point of view, it seems unlikely that non-combustible wood will be widely used at this time due to its cost and ease of handling.